Wheels India Partners with Topy Industries to Strengthen Aluminium Wheel Manufacturing

Wheels India aluminium wheels‘ manufacturing capability is set to receive a boost as Wheels India announced a strategic partnership with Japan-based Topy Industries to strengthen technology, quality, and production efficiency. The collaboration aims to enhance aluminium wheel manufacturing for passenger vehicles and global OEM customers.

Under the partnership, Topy Industries will provide technical know-how, process expertise, and manufacturing support to Wheels India. The focus will be on improving product performance, consistency, and cost competitiveness as demand for lightweight aluminium wheels continues to grow.

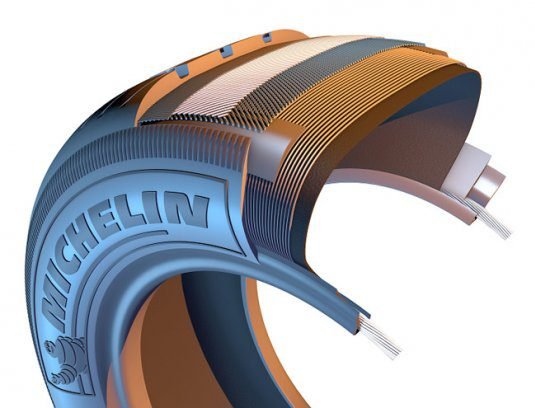

Aluminium wheels play a growing role in modern vehicles due to their lower weight, better heat dissipation, and contribution to improved fuel efficiency and vehicle dynamics. With automakers increasingly focused on emissions reduction and electrification, demand for advanced wheel solutions is rising across domestic and export markets.

Wheels India stated that the partnership aligns with its long-term strategy to strengthen its presence in higher-value automotive components and serve customers with globally competitive products. The company already supplies wheels to several leading OEMs in India and overseas.

The collaboration also reflects a broader trend of Indian auto component manufacturers partnering with global technology leaders to upgrade capabilities and meet evolving industry standards.

Editor’s View

The Wheels India aluminium wheels’ partnership with Topy Industries highlights an important shift within the automotive supply chain. As vehicles become lighter, more efficient, and increasingly electrified, components like wheels are no longer just structural parts but contributors to overall vehicle performance and efficiency.

For the tyre industry, stronger aluminium wheel manufacturing has a direct connection. Wheel design influences tyre fitment, load distribution, heat management, and ride characteristics. As OEMs adopt lighter and more advanced wheel solutions, tyre manufacturers must ensure compatibility in terms of bead design, load ratings, and performance expectations.

This partnership also underlines how Indian component makers are moving up the value chain by absorbing global manufacturing expertise rather than competing only on cost. Such collaborations improve product quality and consistency, which benefits OEMs and downstream suppliers alike, including tyre companies.

In the long run, as India positions itself as a global automotive manufacturing hub, stronger wheel and tyre ecosystems will go hand in hand. Partnerships like this one help ensure that Indian-made components meet international standards, supporting exports, localisation goals, and the next phase of mobility growth.